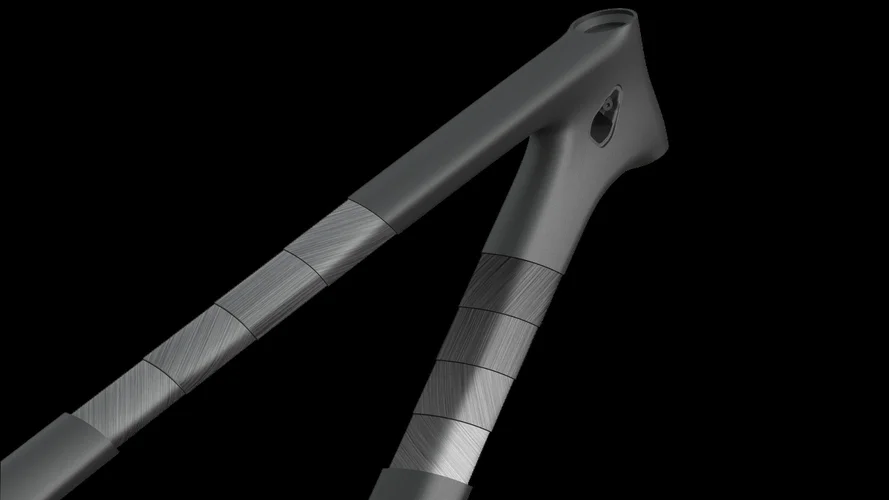

Meeting the most demanding certifications criteria, we hold the world prestigious certifications from the cycling industry: ISO, UCI and EIT, between others. About 30% of our frames are Made in Taiwan, 70% are Made in the Emilia Romagna region, located at the North-East of Italy.